Pipe Fabrications

Anti-corrosion Coatings

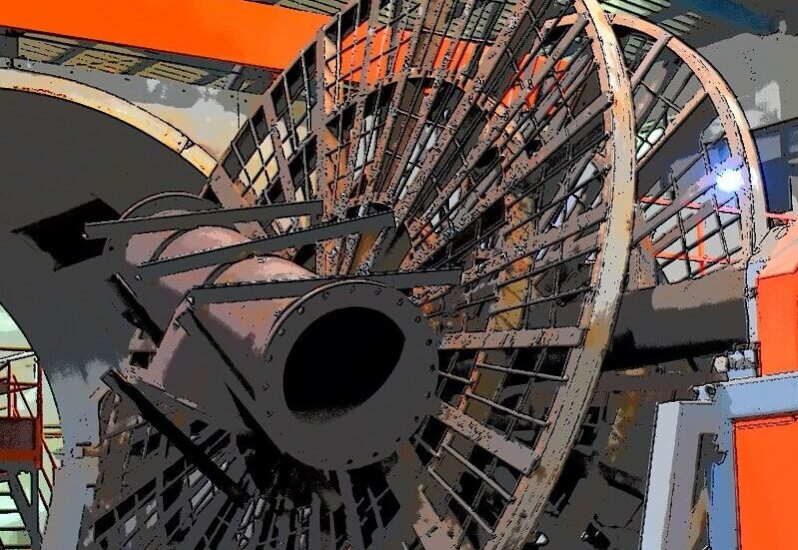

Refurbishment

Polyethylene(PE) plastic lining ensure the longest service in various applications

What we do

Fabrication, PE Lining, Refurbishment, Automet & More

Pipe Fabrication

ABS,DNV and BV qualified welding procedures to ASME IX, A cost-efficient solution for BWTS and EGMS retrofits.

PE Lining & RefurbishMent

Polyethylene(PE) a plastic lining ensure the longest service in various applications.

Metrology and precision

Pipe metrology and precision Prefabrication with Automet®

Core Services

IRL is the first PE Lining company that has completed a Product Design Assessment (PDA) with the American Bureau of Shipping (ABS).

With a full portfolio of ABS,DNV,BV qualified welding procedures to ASME IX, IRL can meet all your requirements for coded carbon steel fabrication, PE lining and proper application of external paint systems under one roof. IRL’s patented pipe refurbishment process allows ship owners to extend the life of their seawater pipes by 10 plus years for a fraction of the price of renewing the pipes.

IRL is the first choice for quality conscious ship managers globally.

- Carbon Steel Pipe Fabrication

- Polyethylene(PE) Lining

- Carbon Steel Pipe Refurbishment

- Installations, Repairs, Replacements

- Pipe Dimensional Control Solutions

- 3D Desgin & Automet® Survey Services

Watch Our Process

Start with A Free Quote For Your Project

or call Now: (852) 5128 3422

“

PE Lined carbon steel pipe is what you use for your seawater pipes when you want the strength and safety of steel and the absolute best and longest lasting coating you can put on that carbon steel pipe, that is why you see so much PE lined steel on LNG vessels.–- Technical Director LNG Fleet

“

We are experienced

We Have Over 10 Years of Experience in The Industry

Founded in 2010 by David Schaus, George Zhuo and VensTse, this partnership has resulted in the world’s leading manufacturer of PE lined carbon steel pipe and provider of refurbished piping.

About us

Providing the Highest Quality PE Lining Services In the Area

IRL fabricates PE lined carbon steel pipe sets for Ballast Water Treatment Systems (BWTS) and Exhaust Gas Management Systems (EGMS).

IRL PE lines carbon steel pipes fabricated by other companies like shipyards and other pipe manufacturers. These pipes are often used in retrofits for BWTS and EGMS as well as seawater pipes for vessel new-buildings. IRL also PE lines carbon steel pipes fabricated by other companies used in the mining, oil and gas, and produced water applications. If the working fluid is seawater, PE lined carbon steel should be considered.

High Quality, Ethically Sourced Materials

Your Satisfaction is Guaranteed

Honest Prices